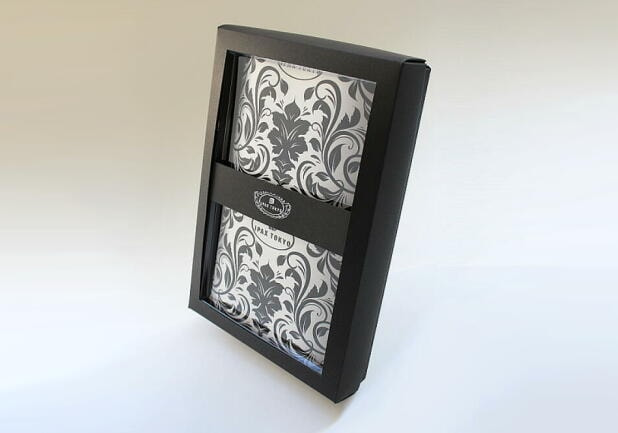

Fiscal 2017 Good Design Award for Hot Mold Press Box (Cocoon-shaped packaging)

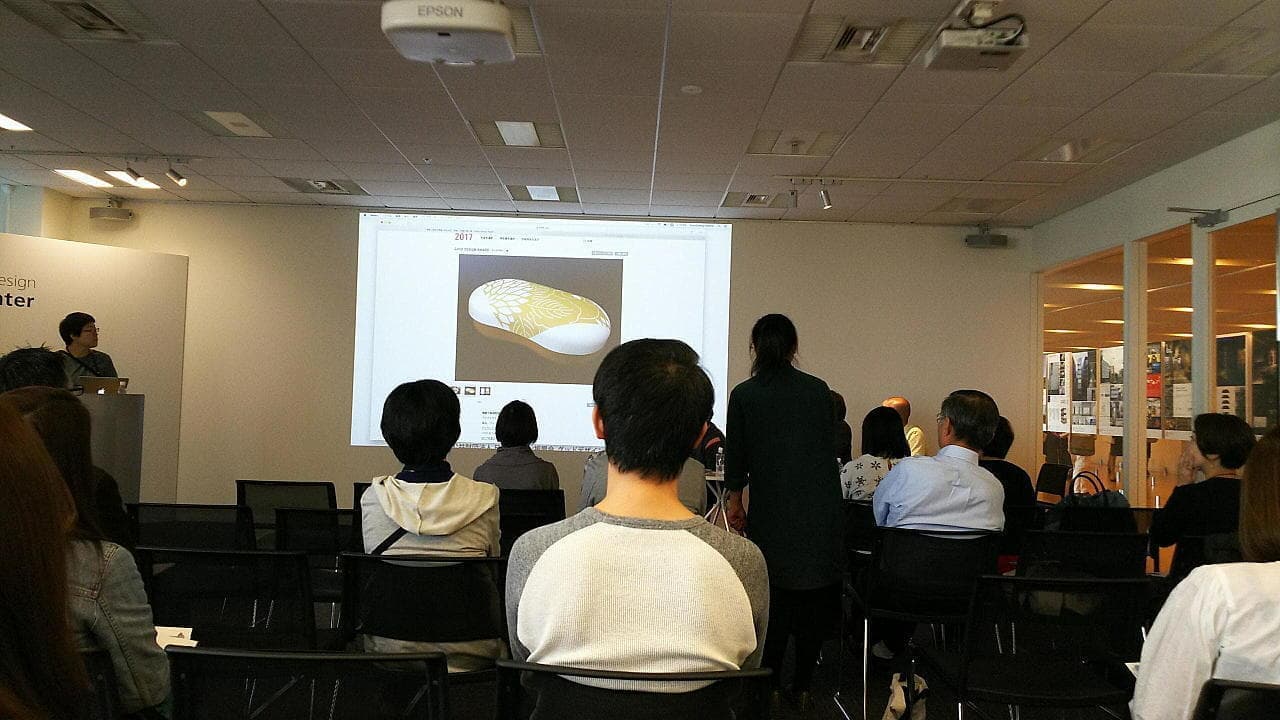

Exhibited at the Tokyo Gift Show for a presentation on newly developed packaging

Promoting Product Development Using Paper Container Technology

DEVELOPMENT PRODUCTS |

/ Introducing Some of Our Products (General Development and IP Creation) |

|---|

PAPER FACE SHIELD

We developed disposable paper face shields to protect the face from droplets by applying paper container manufacturing technology during the COVID-19 pandemic.

●Easy to assemble!

●Hygienic because it is disposable.

●The face shield can be adjusted to two levels.

●The face size can be adjusted to five levels as well.

●The paper and film can be separated for disposal.

●Manufactured in-house using domestically produced raw materials.

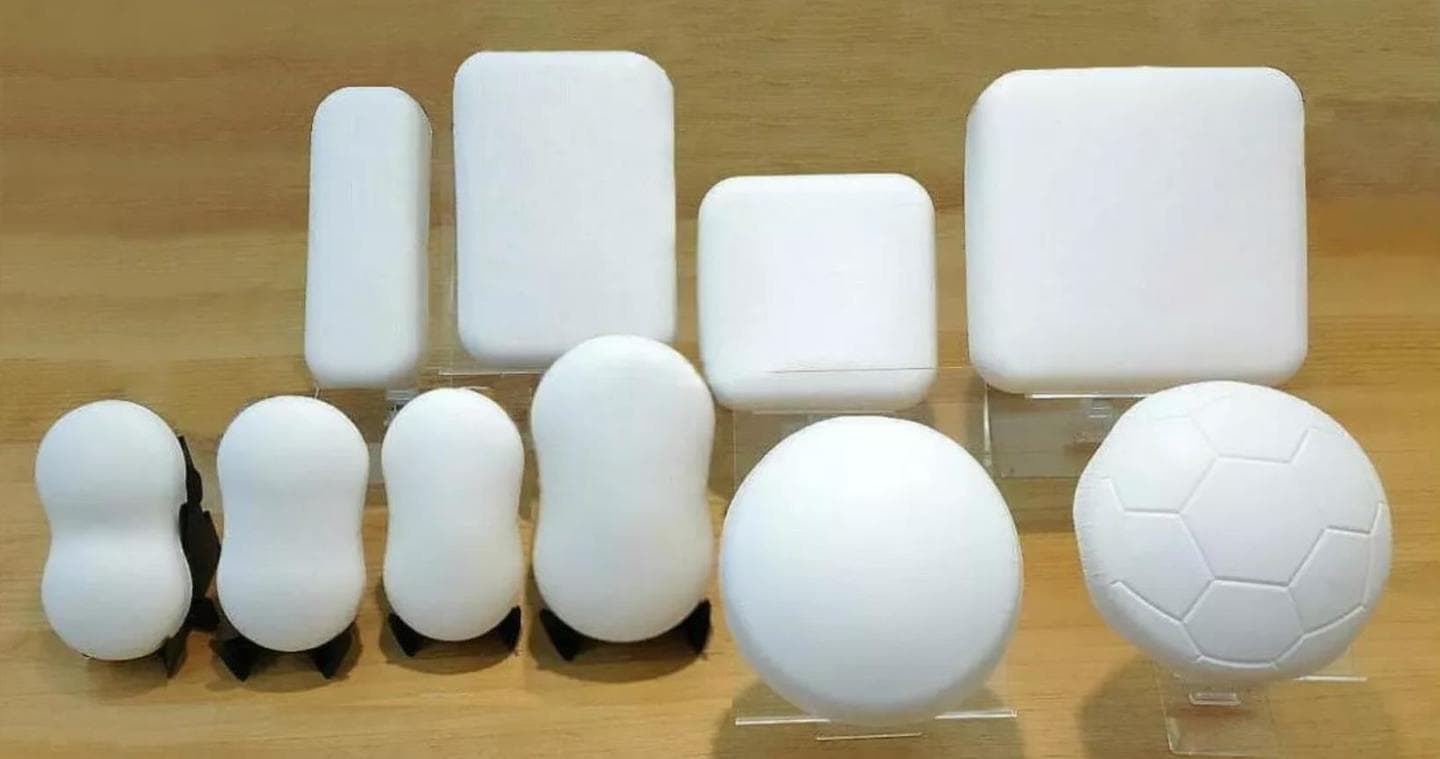

HOT MOLD PRESS BOX

This is a plastic-free paper container featuring multiple curved surfaces.

Winner of the Good Design Award 2017 <Patented>

There are many types of paper molding methods, but I thought that both the beauty of the edges and the deployability of the packaging were excellent.I hope that paper packaging will continue to evolve with this kind of technology.

<Inventor>

Keiji Kanezashi, IPAX IKETANI Co., Ltd.

Yasuhiro Ohara, Kuramae Industries Co., Ltd.

Application filed jointly by two companies

DOME-KAN

2013: Certified by Shizuoka Prefecture as a comprehensive support project for regional industries.

2013: Used for the preserved flowers in the Lexus catalog produced by a world-renowned florist.

2013: Used for the preserved flowers created by a leading preserved flower maker.

2014: Ise-cha tea is now being sold in Europe, the Middle East, and other locations under the direction of Mr. Moriguchi of MîTÉ Co., Ltd.

2015: Distributed to dignitaries at the Emperor's birthday reception at the Japanese Embassy in Washington DC.

2016: Designed and produced a package for promoting Ise-cha tea to the rest of the world at the G-7 Ise-Shima Summit.

<Patented>

FRAME IN BOX

<Patented>

HEATSEAL IN BOX

<Patented>

PAPER CLEAR IN BOX

<Patent pending; material patent acquired by manufacturer>

SHRINK IN BOARD

Attach shrink film to the paper backing

back open on shrink mount

Add box-in function.

<Patented>

There are many types of paper molding methods, but I thought that both the beauty of the edges and the deployability of the packaging were excellent.

The packaging-related IP assets we have introduced are only a fraction of the products we have developed.

We would like to develop new creations with our customers and grow alongside each other.

We are glad that we are contributing to society by generating value that does not exist anywhere else, as well as through our high-quality, stable, and high-speed production of factory line packaging.

The possibilities for packaging are endless...

ISO 9001 certification

JQA-QM5318

The international standard for quality management

ISO 9001 is an international standard for quality management systems.It is the most widespread management system standard, used by more than one million organizations in more than 170 countries around the world.

Benefits of certification

- Improved operational efficiency and reinforcement of organizational structure

- Promotion of legal compliance

- Facilitation of business continuity by enabling work to be visualized

- Management of KPIs (Key Performance Indicators)

- Risk management

- Enhanced corporate value via continuous improvement

- Fulfilment of transaction requirements, including for overseas companies

- Improved social trust and customer satisfaction through quality assurance

FSC®-C140872

FSC®: helping to conserve forests for future generations

FSC® certification is a system that provides consumers with visible products from well-managed forests that offer environmental, social, and economic benefits, thus returning economic benefits to the producers.FSC® certification consists of Forest Management (FM) certification and Chain of Custody (CoC) certification, the latter of which certifies management of processing and distribution processes.In principle, all organizations involved in production, processing, and distribution from the forest to the final product must be certified by the time FSC®-certified products reach consumers.

Antimicrobial Printing

Certifies antimicrobial efficacy and safety

「SIAA Mark」

Registration number: JP0122630A0001Q

What is the SIAA Mark? The Society of International sustaining growth for Antimicrobial Articles (SIAA) is an organization of manufacturers and antimicrobial testing institutions of antimicrobial agents, fungicides, and treated Kohkin/Boukabi products whose goal is the popularization of appropriately treated and secure Kohkin/Boukabi products.With the opinions of industry and customer representatives, specialists, and the government, SIAA maintains rules governing the quality and safety of treated Kohkin products and certifies the labeling and use of SIAA marks, symbols for the security of products that comply with the rules and standards.

Good Design Award

FY2017 and FY2019

Our "Hot Mold Press Box," developed as standalone packaging, won the 2017 Good Design Award.In 2019, "Tomoiru," produced using packaging technology to solve the problem of perinatal loss based on a proposal from the Japan Midwives Association, received the Good Design Award in the Social Contribution category.The Good Design Award is works to improve our lives and society through design.Since its inception in 1957, it has been widely recognized by its symbol, the G mark.Good Design Awards are given to products, architecture, software, systems, services, and many other things that are a part of our lives.Regardless of the form, the Good Design Award recognizes and honors design quality, which is created by people to fulfill some ideal or purpose.

MAP |

/ Map of Headquarters, Facilities and Offices Source: Google Maps |

|---|

Head Office/Nishi-Fuji Facility

Headquarters/Nishi-Fuji Facility /Sales Division/Manufacturing Division/ (Paperboard Packaging Production Plant)

Headquarters: TEL 0544-59-0111 FAX 0544-59-0123

Nishi-Fuji Facility: TEL 0544-59-0011 FAX 0544-59-0123

Kofu Facility

Kofu Facility /Sales Division/Manufacturing Division/

(Paperboard Packaging Production Plant)

TEL: 055-273-1511 FAX: 055-273-4785

Yamamiya Facility

Yamamiya Facility /Sales Division/Manufacturing Division/

(Corrugated Cardboard Case Production Plant)

TEL: 0544-58-2511 FAX: 0544-58-2513

Tokyo Office

Willrose Kodenmacho Room 1103

(Paperboard packaging/Corrugated cardboard case sales)

TEL 03-5825-4111 FAX 03-5825-4164

Overseas Affiliated Companies

IPAX VIETNAM

IPAX VIETNAM COMPANY LIMITED

IPAX SINGAPORE

IPAX SINGAPORE COMPANY LIMITED